Texas A&M Research Team Develop Injectable Hydrogel Bandage that Stops Bleeding Wounds from Inside the Body

Orange County, CA - April 6th, 2018 -

A penetrating injury, from a bullet or any other form of violent intrusion, can be catastrophic, life-changing, and ultimately lead to death. Thanks to a new invention from researchers at Texas A&M, it doesn’t need to be. Drawing inspiration from the unmet need to quickly self-administer materials that can prevent fatality due to excessive blood loss and hemorrhaging, the researchers at the Inspired Nanomaterials and Tissue Engineering Laboratory have successfully developed an injectable bandage to stop bleeding and promote wound healing.

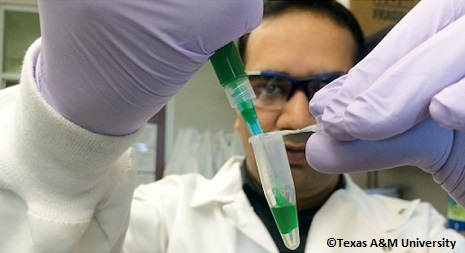

Lead researcher Dr. Akhilesh K. Gaharwar, assistant professor in the Department of Biomedical Engineering at Texas A&M University, published his findings in the online journal Science Direct. Dr. Gaharwar created a hydrogel made up of kappa-carrageenan and nanosilicates (nanoparticles made from common minerals) to promote hemostasis and facilitate wound healing through a controlled release of therapeutics. This gel can be produced for pennies per dose and doesn’t require elaborate handling procedures. Additionally, it can be stored at room temperature, allowing for easy implementation and ideal for battlefield situations.

“Injectable hydrogels are promising materials for achieving hemostasis in case of internal injuries and bleeding, as these biomaterials can be introduced into a wound site using minimally invasive approaches,” said Dr. Gaharwar. “An ideal injectable bandage should solidify after injection in the wound area and promote a natural clotting cascade. In addition, the injectable bandage should initiate wound healing response after achieving hemostasis.”

The hydrogel stays in a liquid state when under mechanical pressure, like during injection, but transforms into a solid as soon as the pressure is released.

As previously mentioned, Dr. Gaharwar’s team used the thickening agent kappa-carrageenan, derived from seaweed, to design this brand of hydrogel. Hydrogels have a similar structure to Jell-O, simulating the structure of human tissues. When mixed with clay-based nanoparticles, kappa-carrageenan transforms into an injectable gelatin. The material interacts with blood by attracting plasma proteins and platelets to its surface and then activates the plasma proteins once attached. This helps to kick-start the clotting process, which in laboratory studies and trials, happens anywhere within two to six minutes.

“Interestingly, we also found that these injectable bandages can show a prolonged release of therapeutics that can be used to heal the wound,” said Giriraj Lokhande, a graduate student in Dr. Gaharwar’s lab and first author of the paper. “The negative surface charge of nanoparticles enabled electrostatic interactions with therapeutics thus resulting in the slow release of therapeutics.”

The team believes the new gel can overcome most of the limitations that plague current methods, such as applying pressure to a wound, which can sometimes cause further damage, and that lack any “biofunctional” abilities. In addition to the gel’s current properties, the researchers hope to embed proteins, growth factors, and other biologics into the material, speeding up the total healing process.

Dr. Gaharwar’s research is funded by the National Science Foundation’s Chemical, Bioengineering, Environmental and Transport Systems Division, and the National Institutes of Health’s National Institute of Biomedical Imaging and Bioengineering.

Contact Ampronix:

Email: info@ampronix.com

International Sales: +1 949-273-8000

Domestic Sales: 1800-400-7972 for US and Canada

Follow Us:

Share This Article:

View our Product Catalog Online Here

About Ampronix

Ampronix is a renowned authorized master distributor of the medical industry's top brands as well as a world-class manufacturer of innovative technology. Since 1982, Ampronix has been dedicated to meeting the growing needs of the medical community with its extensive product knowledge, outstanding service, and state-of-the-art repair facility. Ampronix prides itself on its ability to offer tailored, one-stop solutions at a faster and more cost-effective rate than other manufacturers. Ampronix is an ISO & ANSI/ESD certified facility. To learn more go here.

Texas A&M Research Team Develop Injectable Hydrogel Bandage that Stops Bleeding Wounds from Inside the Body Orange County, CA – April 6th, 2018 – A penetrating injury, from a bullet or any other form of violent intrusion, can be catastrophic, life-changing, and ultimately lead to death. Thanks to a new invention from researchers at Texas A&M, […]