A Research Team Has Developed 3D Resin Ossicular Implants to Help with Hearing Loss

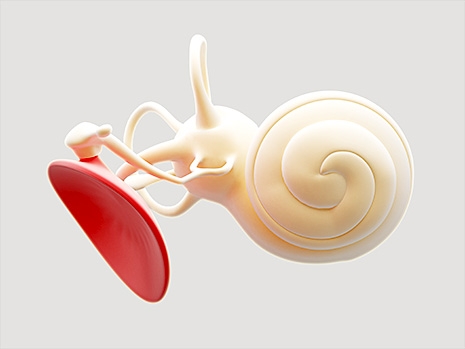

Orange County, CA - December 14th 2017 - Thanks to 3D printing technology, patients suffering from a specific type of hearing loss may find relief. Known as ossicular conductive hearing loss, this results from damage to the ossicles bones responsible for vibration transmission between the ear drum and the cochlea. Currently, the only treatment consists of the surgical replacement of a steel and ceramic prosthesis made individually for each patient. This surgery is plagued with a high failure rate due to the inaccuracy of implant size being larger than the bones they’re replacing.

"The ossicles are very small structures, and one reason the surgery has a high failure rate is thought to be due to incorrect sizing of the prostheses," said study author Jeffrey D. Hirsch, M.D., assistant professor of radiology at the University of Maryland School of Medicine (UMSOM) in Baltimore. "If you could custom-design [prostheses] with a more exact fit, then the procedure should have a higher [success rate]." With that obstacle in mind, Dr. Hirsch turned to 3D printing to replace the damaged bones.

To create exact replicas of the necessary bones researchers used CT scans of an extracted linking bone in the ossicles chain imaged from human cadavers. From these scans, the research team was able to create 3D printed resin reproductions of the bones which proved to be an immediate success. Without prior knowledge of which prosthesis belonged to which cadaver, four surgeons from the research team were able to match their assigned prosthesis to the original cadaver correctly.

Emboldened by this success, the team’s next step will be to print prostheses on biodegradable material. The core goal is to print the prosthesis on a lattice-like material that promotes stem cell growth and will allow for the eventual replacement of the lattice structure with bone.

"This study highlights the core strength of 3D printing – the ability to very accurately reproduce anatomic relationships in space to a sub-millimeter level," says Hirsch. "With these models, it's almost a snap fit."

These findings prove that CT scanners can detect significant differences in the ossicles bones and these differences are easily duplicated with commercially available 3D printing systems. Additionally, surgeons are able to survey and analyze these differences with the naked eye, leading to decreased surgical time. These findings were presented at the Radiological Society of North America (RSNA) conference late last month.

Contact Ampronix:

Email: info@ampronix.com

International Sales: +1 949-273-8000

Domestic Sales: 1800-400-7972 for US and Canada

Follow Us:

Share This Article:

View our Product Catalog Online Here

About Ampronix

Ampronix is a renowned authorized master distributor of the medical industry's top brands as well as a world class manufacturer of innovative technology. Since 1982, Ampronix has been dedicated to meeting the growing needs of the medical community with its extensive product knowledge, outstanding service, and state-of-the-art repair facility. Ampronix prides itself on its ability to offer tailored, one-stop solutions at a faster and more cost effective rate than other manufacturers. Ampronix is an ISO & ANSI/ESD certified facility. To learn more go here.

A Research Team Has Developed 3D Resin Ossicular Implants to Help with Hearing Loss Orange County, CA – December 14th 2017 – Thanks to 3D printing technology, patients suffering from a specific type of hearing loss may find relief. Known as ossicular conductive hearing loss, this results from damage to the ossicles bones responsible for vibration transmission […]